| Sign In | Join Free | My ledscreensign.com |

|

| Sign In | Join Free | My ledscreensign.com |

|

| Categories | Carbon Fiber Parts |

|---|---|

| Brand Name: | crida-model |

| Model Number: | OEM plastic |

| Place of Origin: | Shenzhen China |

| MOQ: | 1 PC |

| Price: | Negotiable |

| Payment Terms: | T/T,L/C,D/A,D/P,Western Union,MoneyGram |

| Supply Ability: | 100000Pcs/ Month |

| Delivery Time: | 7-30 working days |

| Packaging Details: | As the requirement of customer |

| Certification: | ISO9001:2015 |

| Lead time: | Quantity (pieces) 1 - 500 > 500 Lead time (days) 10 To be negotiated |

| After-sale guarantee: | quality issues, free replacement. |

| Products Description: | OEM Manufacturer Carbon Fiber Part, Carbon Fiber Products, Carbon Fiber Molding |

| Size: | Customized size |

| Raw Materials: | Carbon Fiber , Epoxy Resin |

| Product Drawings: | 2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures |

| Supply capacity: | 15000 pieces per Week |

| Carbon Fiber Material: | 1K, 3K, 6K, 12K, 24K (according to customer requirements) |

| Company Info. |

| Shenzhen Crida Model Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

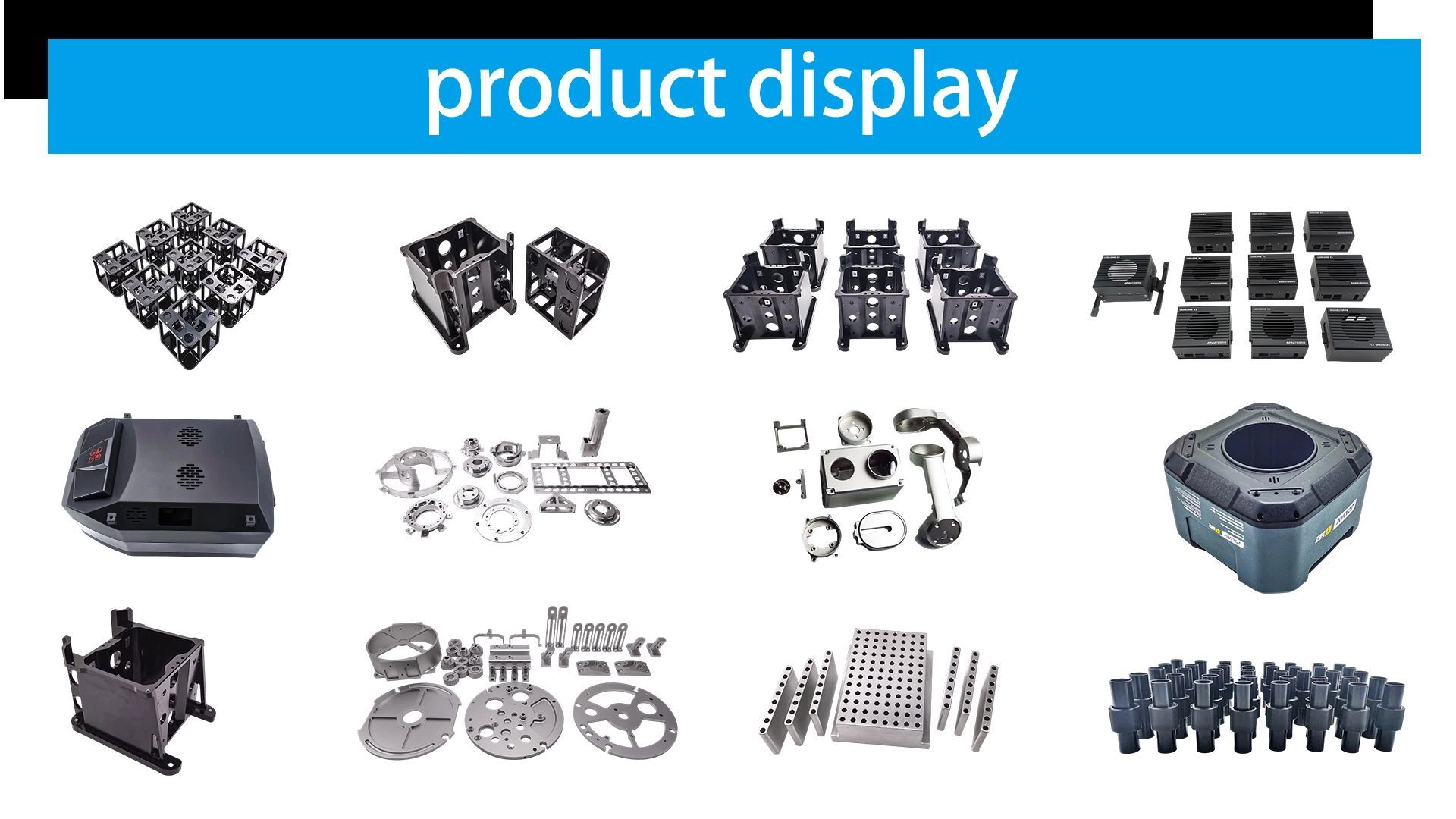

Professional Carbon Fiber Custom Made Machining OEM Custom Carbon Fiber Parts

Highlight: High-Performance Carbon Fiber Brake Disc Engineered, Drone Carbon Fuselage Components, OEM CNC Carbon Fiber Slab.

The Manufacturing Process

Compression molding employs matched metal molds under external pressure in a closed-mold composite manufacturing process. An engineered composite layup is positioned within the open mold cavity; the mold closes, and consolidating pressure is applied. This pressure sustains throughout the oven-based cure cycle. The simultaneous heat and pressure yield near-net-shape components characterized by low void content, high fiber volume fraction, and optimal mechanical properties achievable from the constituent materials.

Technical Parameters

| item | value |

| Surface Roughness: | Ra 0.1~3.2 |

| Thickness | Customized Thickness |

| Industry experience years | 15 years |

| Product Weight | OE Standard Weight, No less weight disc |

| Mold Life | 200,000~1,000,000 shots, or according to customer requirements |

| Micro Machining or Not | Micro Machining |

| Package | With OPP bag or customized, Poly Bag + Inner Box + Carton |

| Customize | Support |

| Dimensions | customizable |

| Shaping Mode | Plastic Injection Mould |

| Surface | 50% Glossy, twill, Matte, Carbon, etc. |

| Function | Mountain Bike Parts, Factory Custom Carbon Fiber Bicycle Fork, transportation, Household Product Mold, Automobile, etc. |

| Service | Carbon Fiber Fabric, Milling, Carbon Fiber, Broaching, Turning, Other Machining Services. |

Quote

Requesting Quotes:

Please submit product details including:

① Geometric parameters (inner/outer diameter, length, dimensional

tolerance)

② Production specs (material, quantity, processing technology)

③ Design requirements (structural needs, surface finish/pattern)

Providing these details allows immediate quoting. Click to contact

our team.

Advantages

Our Competitive Advantages:

30+ dedicated sales professionals providing expert support

Decade-long specialization in automotive modification

Reliable after-sales service commitment

Premium products with precise fitment

Global distribution across domestic & 100+ international markets

1,000m² warehouse enabling ready-stock shipments

Robust packaging ensures transit protection

Various application fields

Industry Applications:

▪︎ Automotive: Bodywork, internal parts, decorations

▪︎ Two-wheelers: Bike/motorcycle bodies and parts

▪︎ Aerospace & Naval: Aircraft, barges, cargo ships, boats, vessels

▪︎ Sporting Goods:

Golf/ski/hockey/badminton/tennis/snooker/trekking poles, archery

stabilizers, billiards cues, safety gear

▪︎ Hobbies: RC copters/toys

▪︎ Civil Engineering: Bridge strengthening

▪︎ Power Sector: Wind turbine blades, oil drilling equipment

▪︎ Industrial Components: Telescopic tubes/poles

▪︎ Consumer Items: Musical instruments, ornamentation rings

For immediate pricing, contact us.

FAQ

|