| Sign In | Join Free | My ledscreensign.com |

|

| Sign In | Join Free | My ledscreensign.com |

|

| Categories | Carbon Fiber Parts |

|---|---|

| Brand Name: | CRIDA |

| Place of Origin: | Shenzhen China |

| MOQ: | 1 PC |

| Price: | Negotiable |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability: | 10000Pcs/ Month |

| Delivery Time: | 15-30 days |

| Packaging Details: | As the requirement of customer |

| Model Number: | OEM |

| Certification: | ISO9001:2015 |

| Part Name: | Carbon Fiber Steering Wheel |

| CNC Machining or Not: | Cnc Machining |

| Material Capabilities: | Aluminum, Hardened Metals, Carbon Fiber |

| Type: | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping M |

| Colors: | Black/Matte Black |

| Logo: | Can be customized |

| Surface: | Glossy/Matte/50% Glossy |

| Thickness: | 0.2-100mm |

| Length: | 10mm-5000mm |

| Technology: | Compression Molding, Autoclave molding |

| Company Info. |

| Shenzhen Crida Model Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

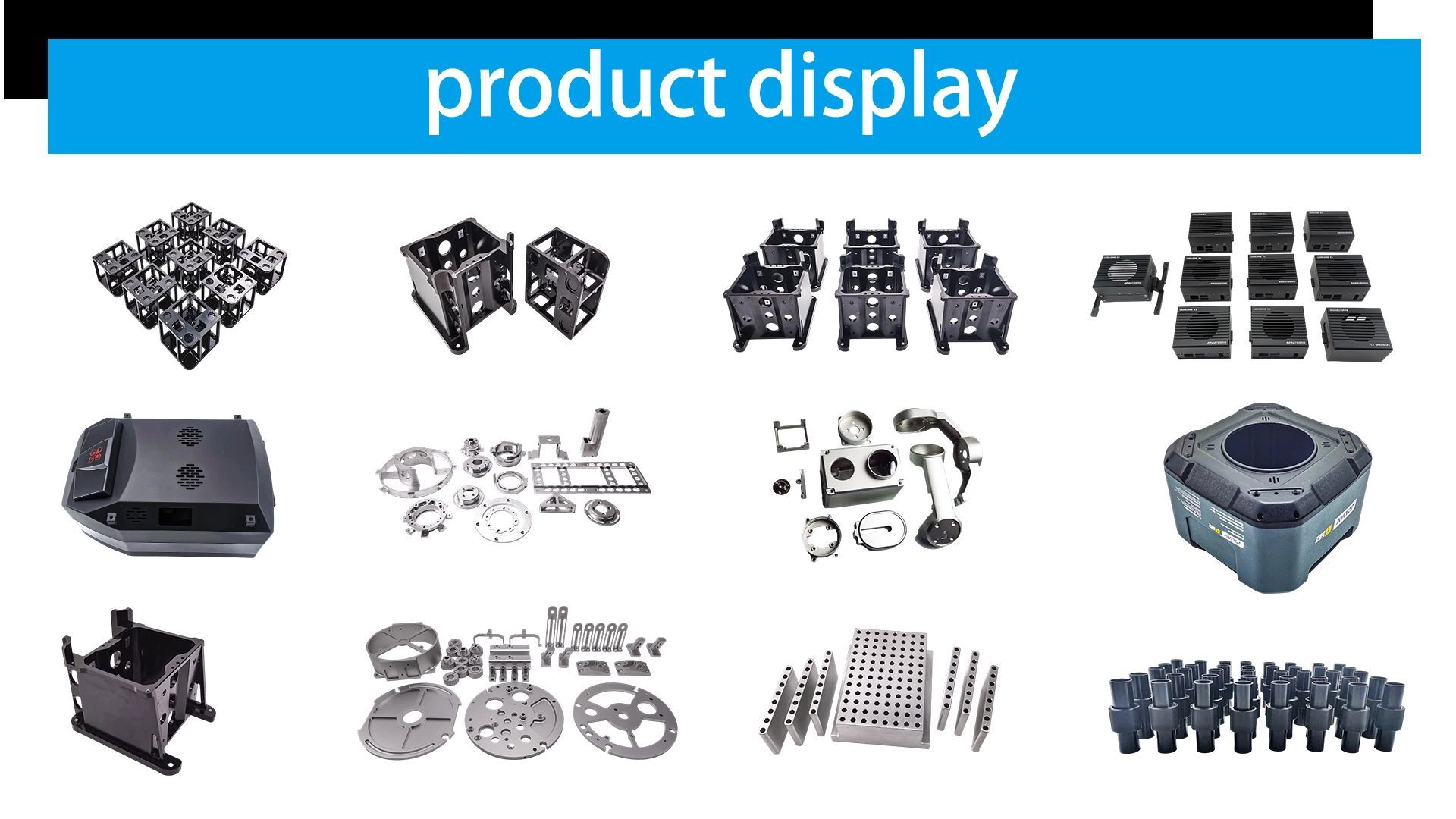

Custom Steering Wheel Simulator Hardware Services Carbon Fiber Aluminum CNC Machined Parts Rubber Grip Manufacturing

Highlight: Customized CNC Carbon Fiber Parts, High-Performance Carbon Fiber Brake Disc Engineered, OEM CNC Carbon Fiber Slab.

The Manufacturing Process

Compression molding is a closed-mold manufacturing process for composites utilizing matched metal molds under external pressure. During this process, an engineered composite material is positioned within the open mold cavity before closure and application of consolidating force. Pressure is maintained throughout the cure cycle, typically conducted in an oven. The simultaneous application of heat and pressure yields composite parts with minimal void content and high fiber volume fraction, producing near-net shape components. This method frequently results in composite parts achieving optimal mechanical properties from their constituent materials.

Technical Parameters

| item | value |

| Color | Customizable Color |

| OEM/ODM | Accept |

| Agency purchasing service scope | Forged wheels and carbon fiber wheels |

| Micro Machining or Not | Micro Machining |

| C Content (%) | Above 90% |

| Installation | Glue tape or screws |

| Shaping Mode | Plastic Injection Mould |

| Certifications: | ISO9001, IS014001, 1s004500, IATF2016 ,QC080000 ,CE ,ROHS. |

| CNC Machining or Not | Cnc Machining |

| Supply Type | Make-to-Order |

| Feature | Carbon Fiber, Resin, Bronze, Carbon Steel, Nylon, etc. |

| Surface | Twill Glossy, Matte, Plain Glossy, Carbon, etc. |

| Keyword | Etching, Broaching, Turning, Plastics injection, Milling, Other Machining Services. |

Quote

To request a quotation for our products, please provide detailed specifications such as inner diameter, outer diameter, length, dimensional tolerance, quantity, structural requirements, surface finish, surface pattern, material, and processing technology.

Based on this information, we can promptly generate a quote. Feel free to contact us to proceed.

Advantages

Exceptional Wear Resistance: Manufactured from premium alloy materials under rigorous quality control, our brake discs deliver outstanding wear resistance during high-load and long-haul operations, extending service life while reducing maintenance costs.

Consistent Braking Performance: The optimized ventilation design ensures superior heat dissipation, maintaining stable braking effectiveness during continuous braking or heavy-duty conditions to enhance fleet safety.

Precision Compatibility: Engineered to international standards, our products guarantee seamless integration with original equipment across diverse vehicle models, minimizing installation issues and boosting operational efficiency.

FAQ

|